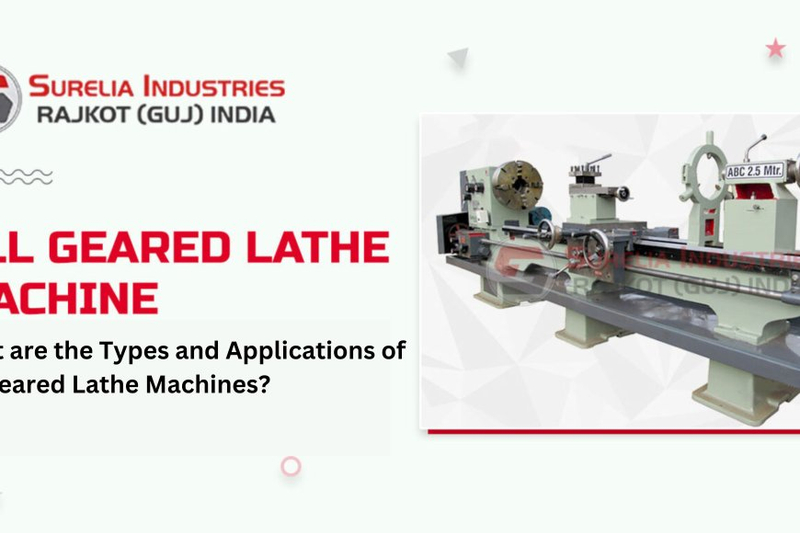

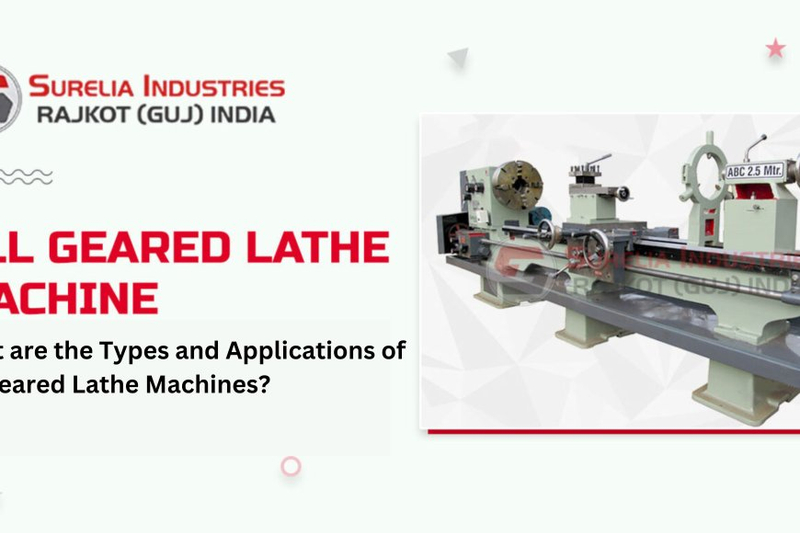

What are the Types and Applications of All Geared Lathe Machines?

In the realm of metalworking, few machines offer the versatility and precision of the lathe. Among these, all geared lathe machines stand out for their robustness and adaptability,

In the realm of metalworking, few machines offer the versatility and precision of the lathe. Among these, all geared lathe machines stand out for their robustness and adaptability,