Why Weighing Scales Are Important in the Manufacturing Industry?

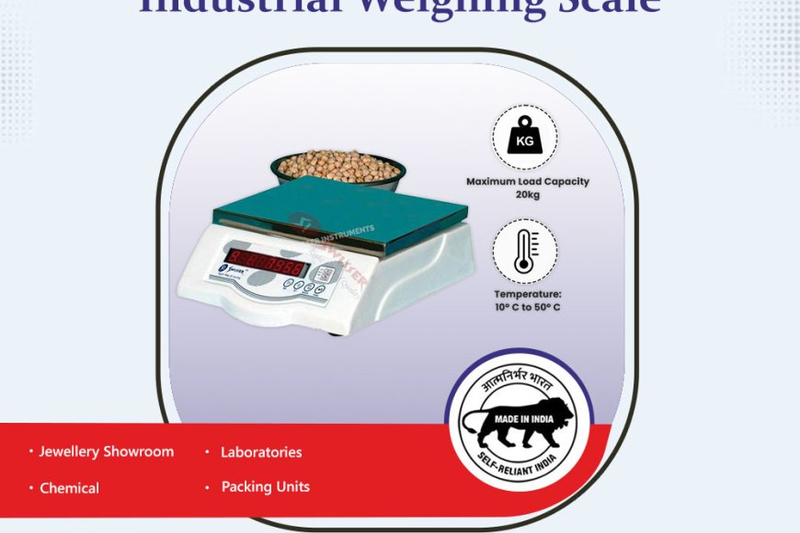

The manufacturing industry requires precision and accuracy in components, raw materials, and finished products. Weighing scales are vital tools for enhancing productivity, ensuring quality control, and promoting cost efficiency.