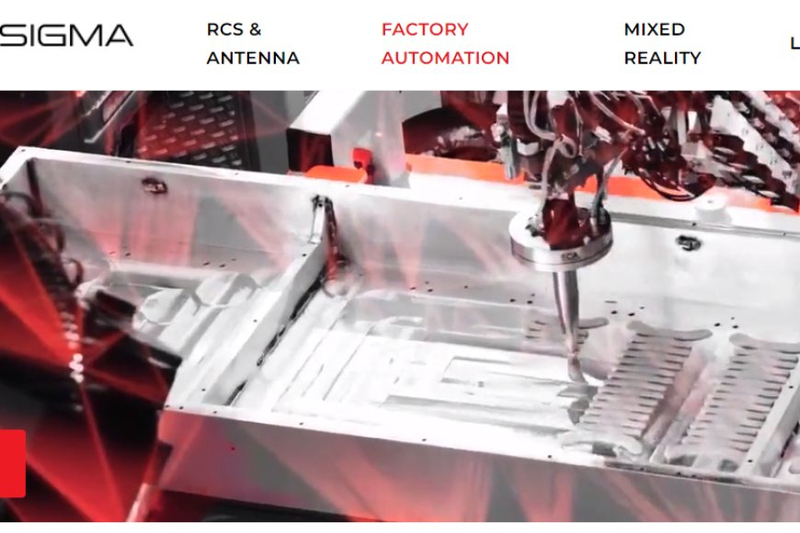

From Assembly Lines to AI: The Evolution of Manufacturing Automation

Manufacturing has come a long way from the days of manual labor to the era of sophisticated automation powered by artificial intelligence (AI). The journey of automation in manufacturing, from the introduction of assembly lines to the integration of AI-driven systems, showcases a remarkable evolution that has revolutionized the industry.