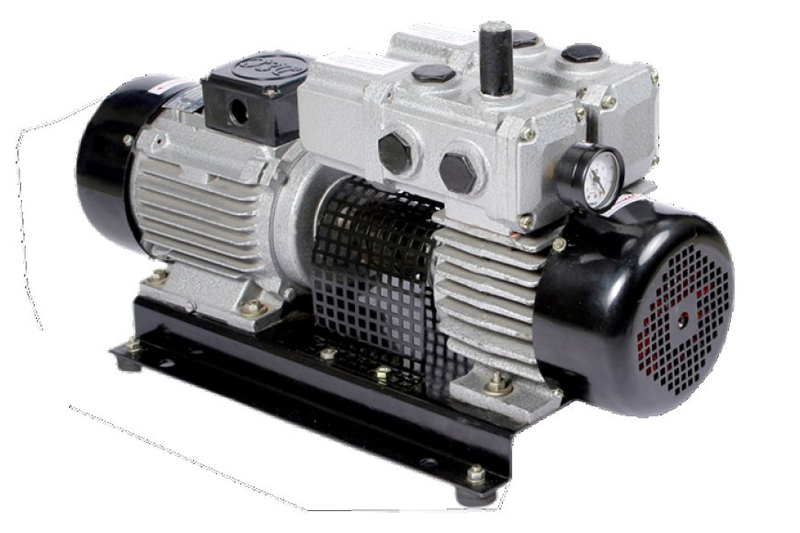

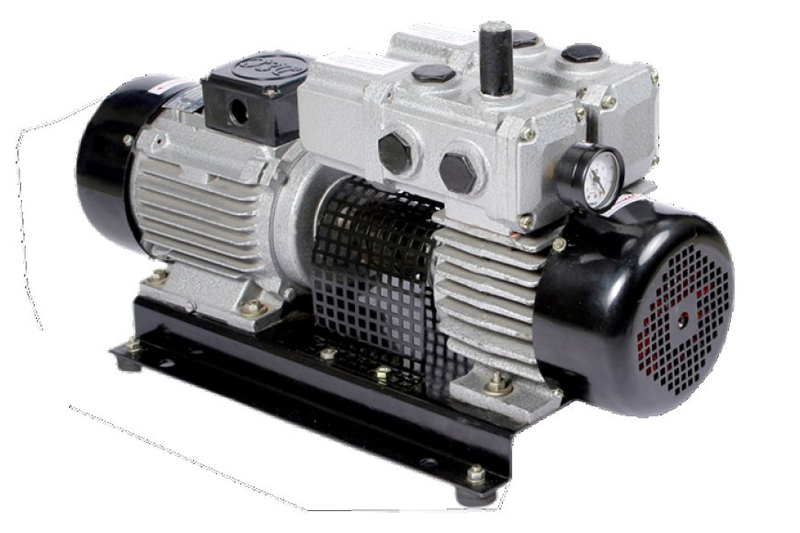

Dry Vacuum Pumps: Powering Industrial Precision

Dry Vacuum Pump stand as the unsung heroes within the realm of industrial machinery, silently facilitating critical operations across various sectors.

Dry Vacuum Pump stand as the unsung heroes within the realm of industrial machinery, silently facilitating critical operations across various sectors.