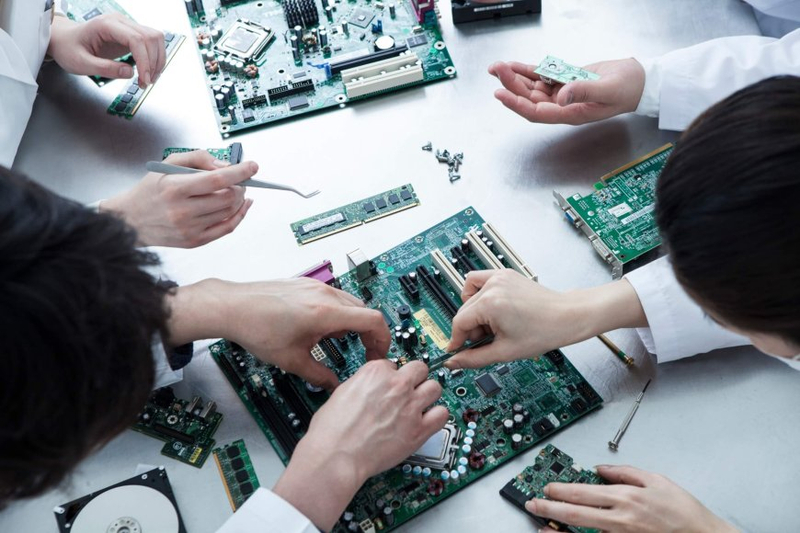

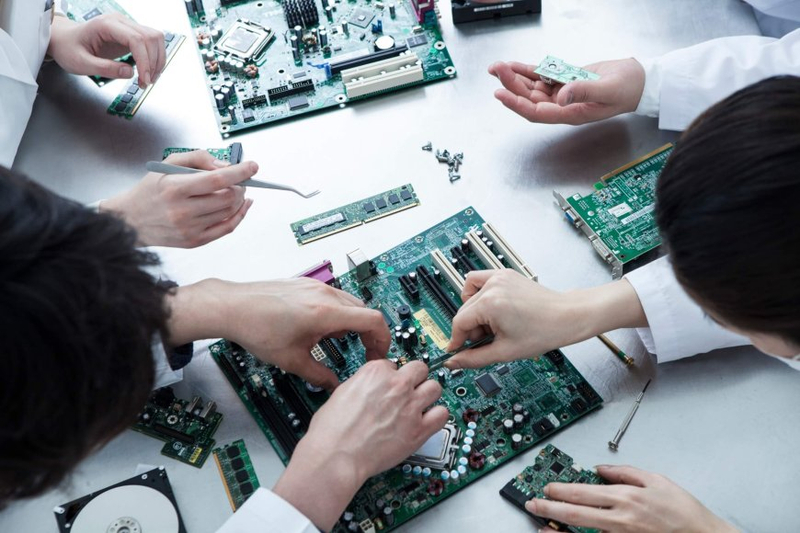

Choosing the best printed circuit board assembly partner

This article talks about the factors that can help you in choosing the best circuit board manufacturer. Let’s dive in.

This article talks about the factors that can help you in choosing the best circuit board manufacturer. Let’s dive in.