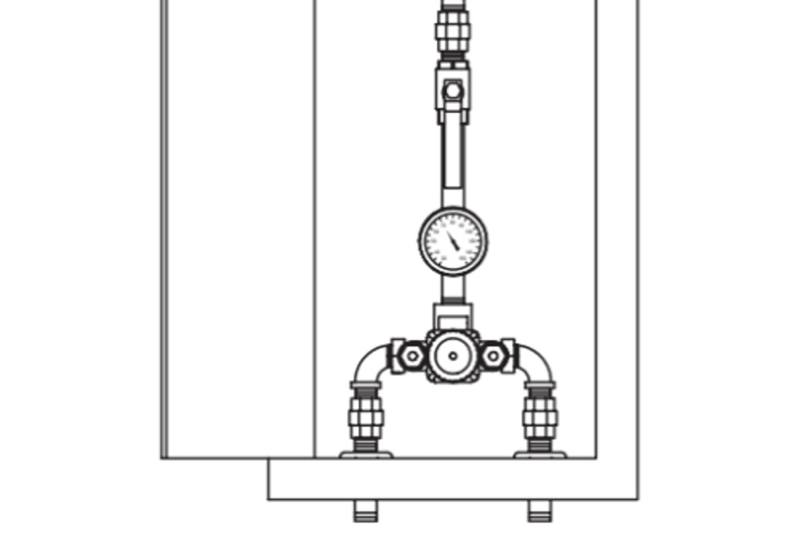

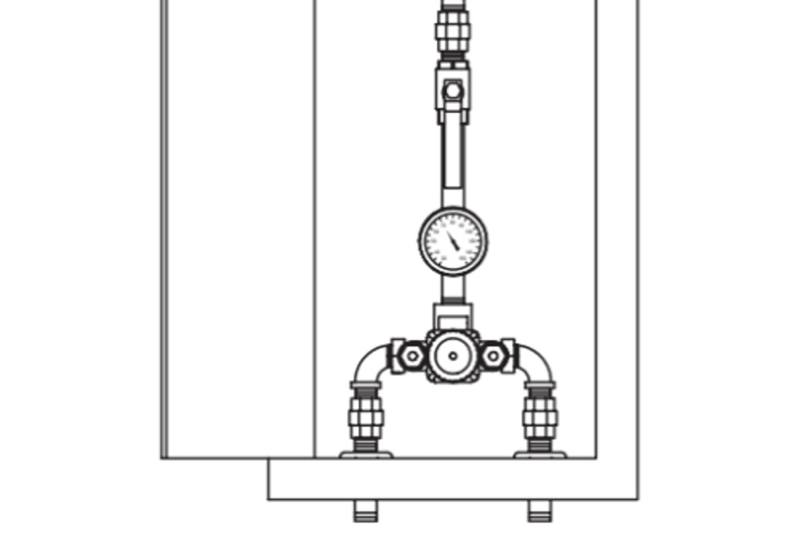

Basic Maintenance for a Symmons Mixing Valve (7-500B Symmons TempControl TMV)

That said, these Symmons mixing valves still need periodic attention. Here’s what you need to know.

That said, these Symmons mixing valves still need periodic attention. Here’s what you need to know.